Damp Floor Treatment Chester

Why Should You Damp Proof Concrete Floors in Chester?

When dealing with concrete, damp proofing the floor is essential. Moisture rises from the ground through the concrete through capillary action, and changes in the environment can have a big impact on the water levels. For example, landscaping can mean that plants and trees are no longer absorbing the water in the ground and moisture levels will rise.

There are a few options for tackling dampness in concrete floors, including digging up the existing flooring and installing a new damp-proof membrane to take the edge off before installing a new concrete slab. Or, fully isolate the dampness by using a surface damp-proof membrane.

What Are Damp Proof Membranes?

The best solution for floor damp proofing in Chester, Damp Proof Membrane (DPM for short) are rolls of strong polythene that protect against moisture. There are different gauges (thicknesses) of DPM, however, the British Standards propose that a sheet should be at least a 1200 gauge.

Damp-proof membranes work by creating an air gap, which allows the excess water to evaporate. The installation process requires a careful hand, as any tears in the plastic membrane sheet will allow moisture to penetrate the protective layer.

How To Install Damp Proof Membrane on Concrete Floors in Chester

Installing a floor membrane on concrete to fight dampness is a relatively simple process, but getting it wrong can cause even more issues down the road. When installing an underlay process, roll out the damp-proof membrane the same way you do a carpet and cut to size.

The next layer should be rolled out overlapping the edges of the membrane and seal the joints with waterproof tape. Once both widths are in alignment, remove the backing paper and press down both sections are sealed together and repeat the process until the whole floor is covered.

All extensions and new builds are required to have a damp-proof membrane installed, and a durable 1200 gauge DPM is essential during the initial construction process. The membrane should be placed between the hard earth and concrete slab to create a strong layer that repels dampness.

For existing concrete floors, an epoxy floor coating is a fail-safe solution that is ideal for when an existing DPM has either failed or hasn’t been installed in the first place. Low-odour and solvent-free, an epoxy coating can be applied directly on top of damp floors.

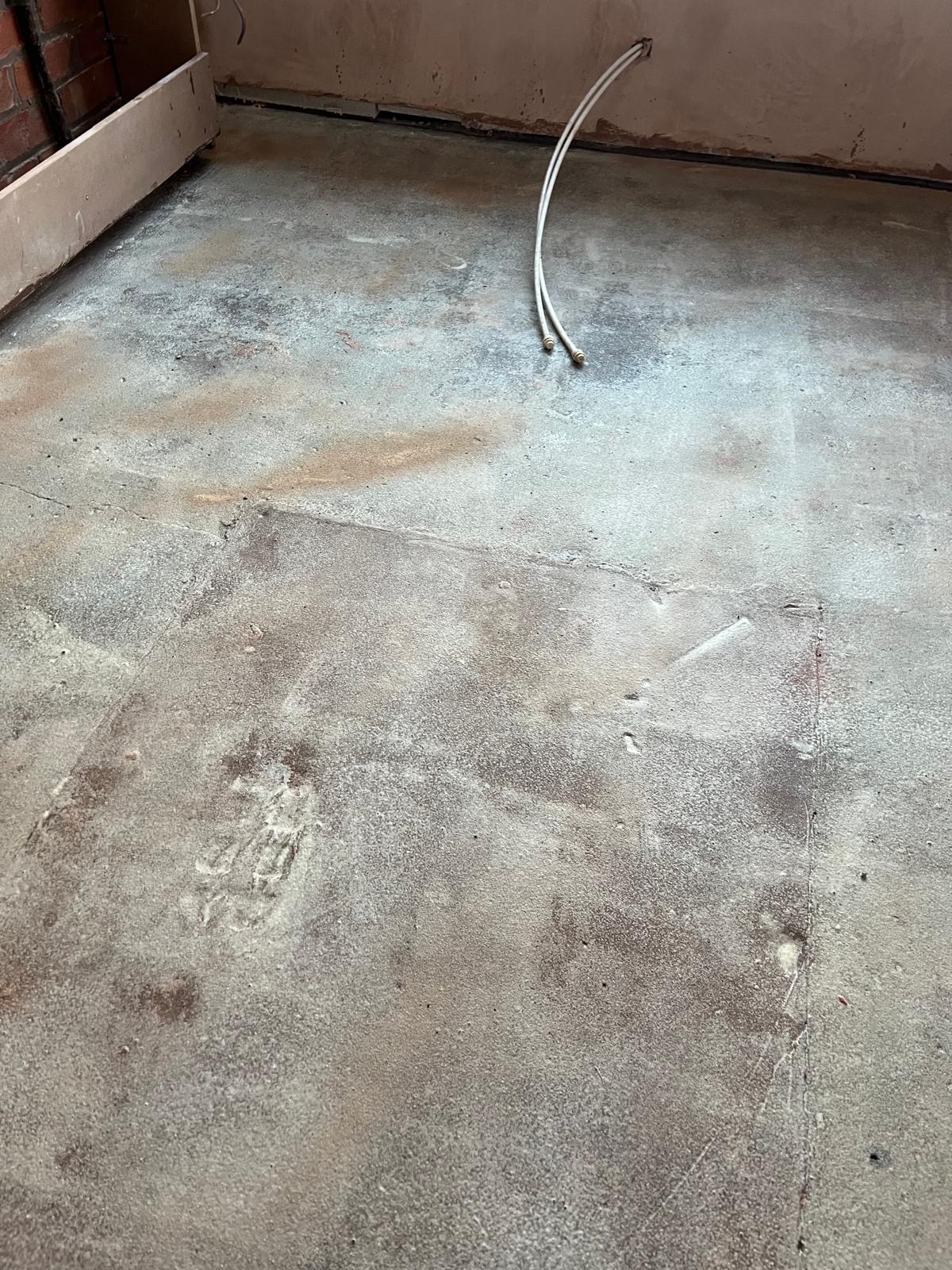

Causes of damp concrete floor in Chester

The most common causes of damp concrete floors are:

• High Water-to-Cement Ratio

• Moisture Vapour Transmission

• Insufficient Curing

• Leaking pipes

• Poor ventilation

If left untreated, the moisture vapour trapped in the slab under the flooring can liquefy at the slightest temperature change, leading to several problems, including total flooring failure and breakdown of the concrete moisture barrier system and adhesive deterioration.

Damp floor treatment Chester

Floors can suffer easily from water ingress. Damp in concrete floors are much more difficult to treat than damp walls. At Quirks, our experts can damp proof your floors at affordable prices Chester. Our damp specialists will survey your building and offer recommendations to you for damp floor treatment. First, you need to fix the problem, identify the moisture problem’s source, and then take the necessary steps to dry out the floors.

Epoxy Resin for Damp Concrete Floors Chester

Our damp specialists can also consider the coating with epoxy resin. It is applied around the floor’s surface to stop it and prevent damp migrating to the floors. It is a simple process that requires the floor to be prepared and cleaned and removes any of the existing floorings.

Damp Proof Floor Coating Chester

In this, we apply a damp proof coating onto the concrete floor with a brush or roller. When a technician carries out the process, the surface must be dry and clean before applying the damp proof floor coating.

What Differentiates a DPC from a Damp Proof Membrane

A DPC (damp-proof course) is a damp proofing barrier installed in a structure to prevent moisture from rising through capillarity. Such water movements can occur during situations like rising damp, resulting from your property sucking up water from the grounds.

A damp course can be horizontal or vertical, and you lay it underneath all masonry walls irrespective of whether they are partition or load-bearing.

On the other hand, A damp proofing membrane (DPM) is a thin material placed to solve a damp problem. An example of a damp proofing membrane is polyethylene sheeting applied under concrete slabs to counter water absorption by capillary action.

A damp proofing membrane is one of the top materials used in damp proofing. Damp proofing involves moisture control on floors and building walls. The process aims to make sure your interior spaces are dry and cosy.